3D EAU Studies

Ensuring optimal performance of collective sanitation through continuous monitoring of CSOs

Issues

How to ensure the optimal performance of collective sanitation ?

While Combined Sewer Overflows (CSOs) are essential components of the existing sewer system, their discharge must be closely monitored to prioritize investigations and investments aimed at ensuring the efficiency of the sewer network

Comment optimiser le stockage et la gestion des eaux pluviales ?

Innovative solutions by 3D EAU

Monitoring of storm overflows by hydraulic modelling of a head/discharge law

If you want to implement or improve the reliability of instrumentation at your discharge points, 3D EAU offers hydraulic expertise for each measurement site to ensure accuracy and ease of operation.

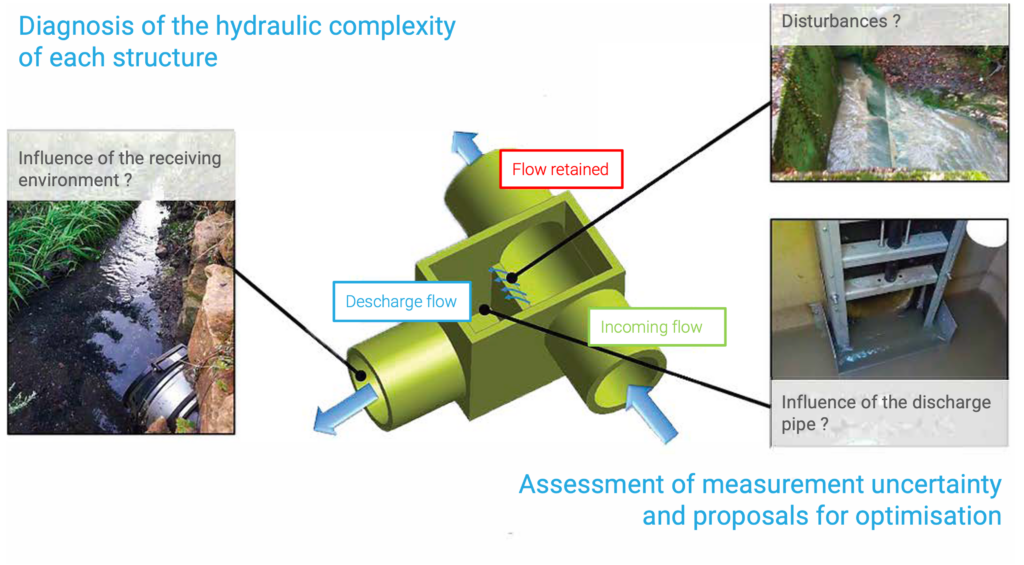

Hydraulic analysis of the discharge point

After visiting the structure to measure its geometry, 3D EAU analyses its hydraulic operation. This essential stage provides an understanding of the degree of hydraulic complexity of the structure and thus enables us to plan the numerical simulations that need to be carried out to ensure that the model is representative of the actual operation of the structure.

Modelling tailored to the challenges of the storm overflow

Estimate the flow rate discharged through the pumping station’s overflow pipe using water head measurements and orifice flow equations derived from a European research project.

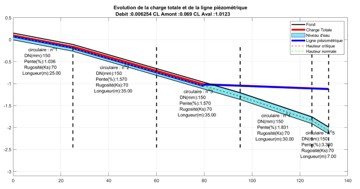

0D/1D modelling

Estimate flow using non-contact water level measurements combined with 0D modeling (literature-based flow laws) or 1D modeling (streamline analysis) to calibrate measurement devices.

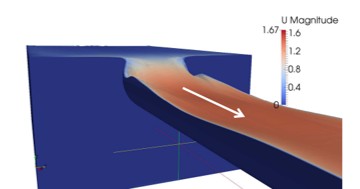

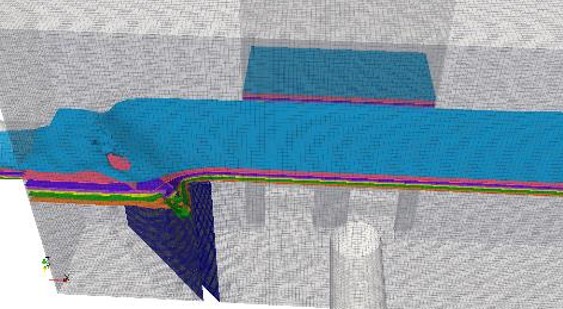

CFD (3D modelling)

Measure flow using non-contact water level monitoring and 3D flow modeling to ensure highly precise calibration of the measurement device.

Elaborating the flow monitoring solution

At the end of the study, 3D EAU recommends the following:

Type and number of water level sensors to be installed

Location of water level sensors to be installed

Head / discharge calibration laws

Quantification of measurement uncertainty

Control protocol

Here’s an example of how CFD can improve data collection on sewer efficiency.

Benefits

Enhanced insight into the performance of the sewer system

Site-specific instrumentation recommendations

Simplified computation of sewer spills through hydraulic modeling (0D/1D/3D) tailored to the site’s needs

Maximizing investment and operational cost efficiency

Scientifically validated approach, with successful implementation on hundreds of CSOs