3D EAU studies

Optimising a pumping reservoir

Issues

How to ensure the efficient working of a pumping station ?

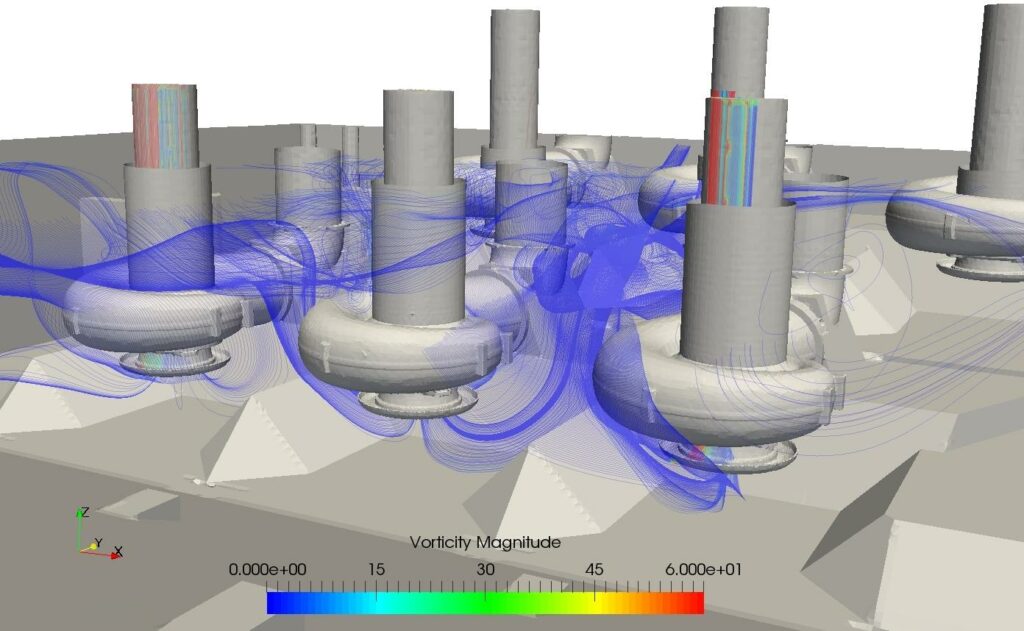

Pumping stations follow the ANSI/HI 9.8-1998 standard to prevent vortices, turbulence, and uneven flow, ensuring efficiency and longevity. If compliance is not feasible due to site constraints, verification is crucial. Computational simulations and physical modeling help assess hydraulic conditions, ensuring proper operation and minimizing inefficiencies under real-world conditions.

The benchmark for pump chamber design is the American standard (ANSI/HI 9.8-1998). This defines the criteria to be met when designing pumping stations to prevent vertices formation. This standard also describes designs known to be conducive to the formation of such unwanted phenomena, which should be avoided.

Firstly, you gain a better understanding of how your facility interacts with its environment. The various optimisation scenarios available to you allow you to see how the water flows through the pumping reservoir and to test different configurations. This visualisation helps to identify areas of turbulence or stagnation that could affect the efficiency of your system and to simulate their impact on the flow of water.

Secondly, visualising the pumping reservoir enables a predictive maintenance process to be put in place. In this way, problems can be anticipated before they occur. This saves time and resources, particularly in terms of maintenance.

Proposed solution

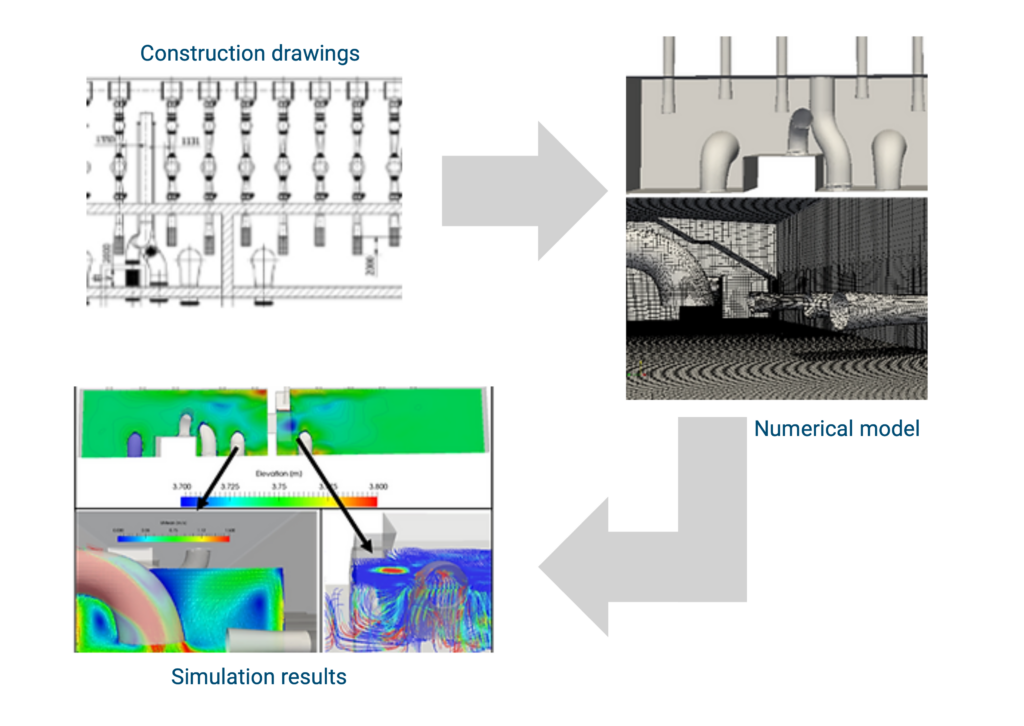

A CFD approach to optimizing pumping stations

- Visualisation of the structure in operation in its hydraulic environment

- Diagnosis of operation and optimisation proposals

- Simulation of optimisation scenarios for the facility